Planning your Sydney build and weighing up Hebel against foam cladding options? You're looking at three very different approaches to walls and insulation, each with distinct advantages.

We've been installing Hebel AAC panels, EPS foam, and XPS foam systems across Sydney for years. We've seen which materials work where – and more importantly, where they don't. Every project teaches us something new about getting the most from these systems.

Here's our honest breakdown of how these materials stack up against each other, based on real projects and real results.

Let's dive into the real-world differences between these popular building materials and help you choose the right one for your specific project.

🔽 Jump straight to performance comparison

Key Takeaways

- Choose Hebel when: You need structural walls, fire resistance (BAL zones), or acoustic performance

- Choose EPS foam when: You want maximum insulation value, lower costs, or lightweight applications

- Choose XPS foam when: You need higher compressive strength and superior moisture resistance for demanding applications

- Hybrid approach: Hebel for structure, foam for pure insulation

The Key Differences: Hebel vs EPS vs XPS

Hebel AAC: Australia's only locally-made autoclaved aerated concrete. It's a structural building material that replaces traditional framing while providing insulation, fire resistance, and acoustic properties in one system.

EPS Foam: Lightweight polystyrene insulation that's 98% trapped air. Non-structural but delivers exceptional R-values at low cost. Requires a separate structural frame.

XPS Foam: Premium extruded polystyrene with higher density and strength than EPS. Superior moisture resistance and compressive strength make it ideal for demanding applications like under-slab insulation.

Performance Face-Off: The Numbers Don't Lie

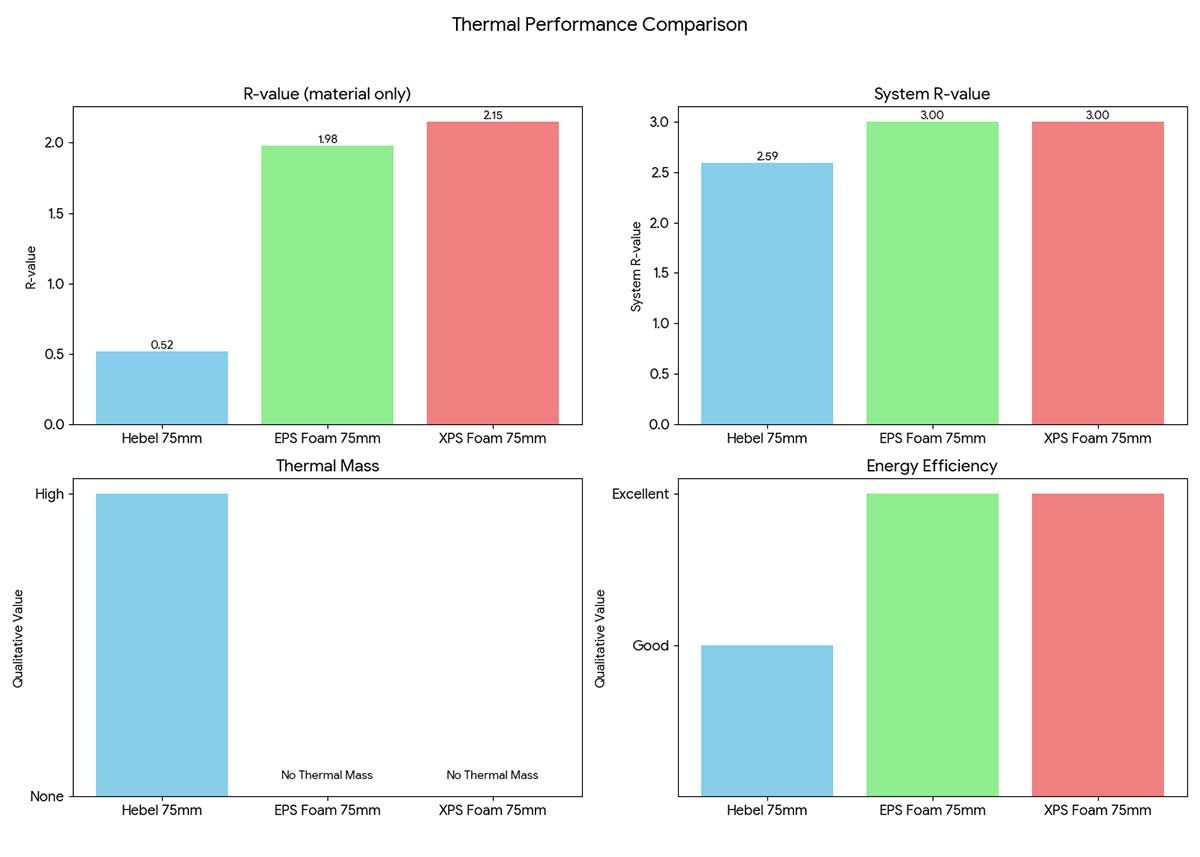

Thermal Performance Comparison

| Property | Hebel 75mm | EPS Foam 75mm | XPS Foam 75mm | Winner |

|---|---|---|---|---|

| R-value (material only) | 0.52 | 1.98 | 2.15-2.27 | XPS Foam |

| System R-value | 1.61-3.57 | >3.0 | >3.0 | Tie (Foams) |

| Thermal mass | High | None | None | Hebel |

| Energy efficiency | Good | Excellent | Excellent | Tie (Foams) |

Reality check: Both EPS and XPS deliver superior insulation per millimetre, with XPS having a slight R-value edge. But here's what the R-value doesn't tell you - Hebel's modest panel R-value of 0.52 contributes to a total system R-value of 1.61-3.57 when you factor in the frame, air gaps, sarking, and internal linings. It's the complete wall assembly that determines final thermal performance, not just the panel.

Foam-based systems typically achieve total R-values above 3.0, making them superior pure insulators. However, Hebel's thermal mass helps regulate temperature swings throughout the day - something polystyrene foams simply can't provide.

Structural Strength Reality

| Property | Hebel | EPS Foam | XPS Foam | Notes |

|---|---|---|---|---|

| Compressive strength | 4.0+ MPa | 0.105 MPa | >0.35 MPa | XPS 3x stronger than EPS |

| Load-bearing capacity | Yes (3 storeys) | No | No | Robust structural qualities |

| Requires frame | No | Yes | Yes | Cost implication |

| Under-slab use | Not suitable | Limited | Ideal | XPS handles concrete loads |

The bottom line:

Hebel has more robust qualities than EPS or XPS, including better structural integrity (especially in products like Hebel blocks). However, in many applications such as wall systems, all three materials—Hebel panels, EPS, and XPS—are non-loadbearing and typically require a structural frame for support. That said, XPS has significantly higher compressive strength than EPS, making it suitable for higher-load applications like under concrete slabs.

Fire Safety Comparison

| Aspect | Hebel | EPS Foam | XPS Foam |

|---|---|---|---|

| Material type | Non-combustible | Combustible (FR treated) | Combustible (FR treated) |

| BAL rating | All levels (including BAL-FZ) | Up to BAL-40 only | Up to BAL-40 only |

| Fire Resistance Level | Up to 240/240/240 | Depends on system | Depends on system |

| Bushfire zones | ✅ Compliant | ⚠️ Limited | ⚠️ Limited |

For bushfire-prone Sydney areas: Hebel wins hands down.

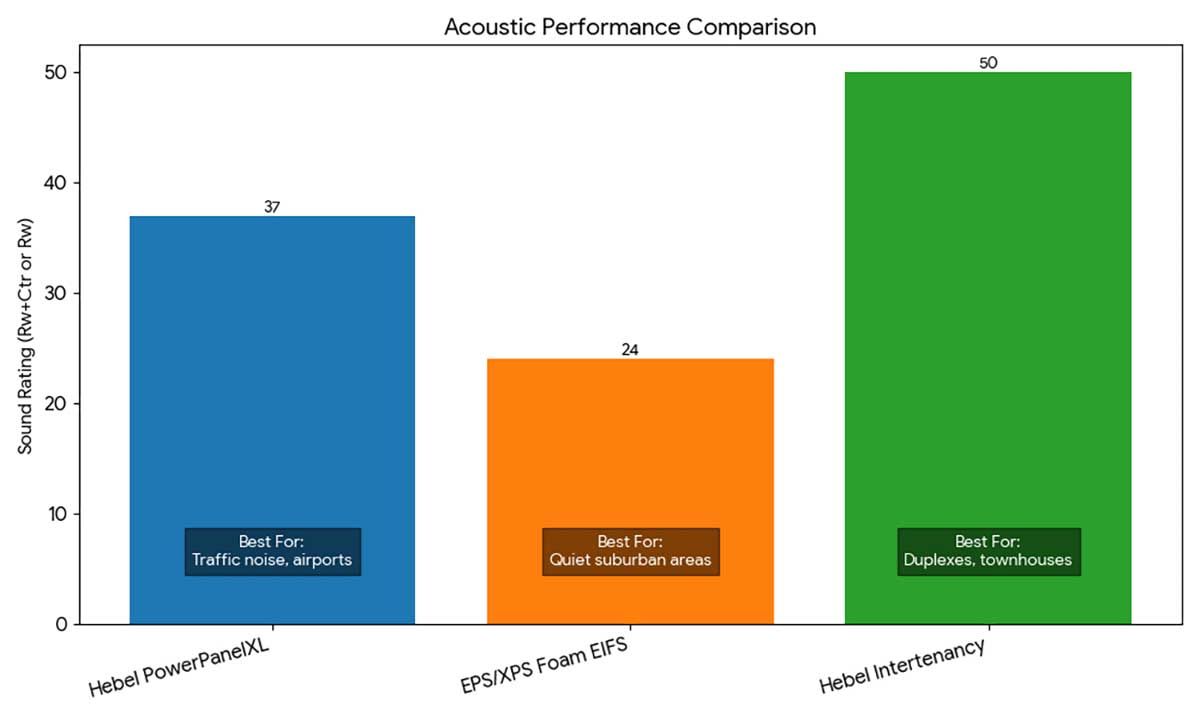

Acoustic Performance

| System | Sound Rating | Technical Detail | Best For |

|---|---|---|---|

| Hebel PowerPanelXL | Rw+Ctr = 35-39 | Ctr correction for low-frequency traffic noise | Traffic noise, airports |

| EPS/XPS Foam EIFS | Rw = 23-25 | Standard system rating | Quiet suburban areas |

| Hebel Intertenancy | Rw+Ctr = 50+ | Purpose-built acoustic separation | Duplexes, townhouses |

Near busy roads or flight paths? Hebel's mass delivers superior sound blocking. The Ctr rating specifically measures performance against low-frequency noise like traffic rumble - exactly what you need near busy roads. Both EPS and XPS have negligible acoustic insulation properties due to their low mass.

When to Choose Each Material

Choose Hebel AAC When:

New home construction where you need:

- Load-bearing external walls

- Fire compliance in BAL zones

- Superior sound insulation

- Integrated structure + insulation

- That solid, impact-resistant feel

Choose EPS Foam When:

Insulation-focused projects where you want:

- Maximum R-value per dollar spent

- Lightweight retrofit insulation

- Custom shapes and profiles

- Separate structural frame anyway

- Moisture-resistant applications

Choose XPS Foam When:

High-performance insulation projects where you need:

- Superior compressive strength for load-bearing insulation (e.g., under slabs)

- Maximum moisture resistance for wet or below-grade areas

- Higher R-value in a thinner profile

- Exceptional durability and rigidity

The Hybrid Approach (Our Recommendation)

For most new Sydney homes, we recommend combining materials:

- Ground floor external walls: Hebel (structure + fire + acoustic)

- Under-slab insulation: XPS (strength + moisture resistance)

- Roof insulation: EPS (maximum R-value for cost)

- Floor insulation: EPS (cost-effective)

This approach optimises performance and cost by using each material where it performs best.

Installation Reality Check

Hebel Installation Process

- Requires specialist, accredited installers

- Large panels need lifting equipment

- 150m² home completed in 3 days

- Weather-resistant installation

- Brings lock-up forward by 2-4 weeks

EPS/XPS Installation Process

- General carpentry trades can install

- Lightweight, easy to cut and shape

- No special equipment needed

- Can install in most weather

- Rapid cladding over existing frame

Speed winner: Depends on your project. Hebel for new structural walls, EPS/XPS for insulation-only work.

Long-term Performance & Maintenance

All systems need similar maintenance when finished with quality acrylic render:

Maintenance Schedule

- Annual washing: Low-pressure cleaning

- Bi-annual inspection: Check sealant joints

- 7-10 year recoat: Full acrylic membrane renewal

Durability & Moisture Management

| Aspect | Hebel | EPS Foam | XPS Foam |

|---|---|---|---|

| Impact resistance | High (solid masonry) | Moderate (soft core) | High (denser core) |

| Water absorption | Must be coated (porous AAC) | 2-4% by volume | <1% by volume |

| System moisture strategy | Single barrier (acrylic coating) | Dual barrier (EPS + sarking) | Dual barrier (XPS + sarking) |

| UV sensitivity | Low | High (needs protection) | High (needs protection) |

| Chemical resistance | Good | Poor (petroleum solvents) | Poor (petroleum solvents) |

| Expected lifespan | 50+ years | 50+ years | 50+ years |

Critical difference: Hebel systems rely entirely on their external acrylic coating as the primary moisture barrier. If this fails, water can penetrate the porous AAC substrate. Foam systems typically include breathable sarking behind the panel, creating a secondary drainage plane for redundancy. XPS offers superior moisture resistance over EPS due to its extruded, non-porous structure.

Maintenance tip: All three systems rely heavily on their external coating. Don't skimp on render quality or maintenance.

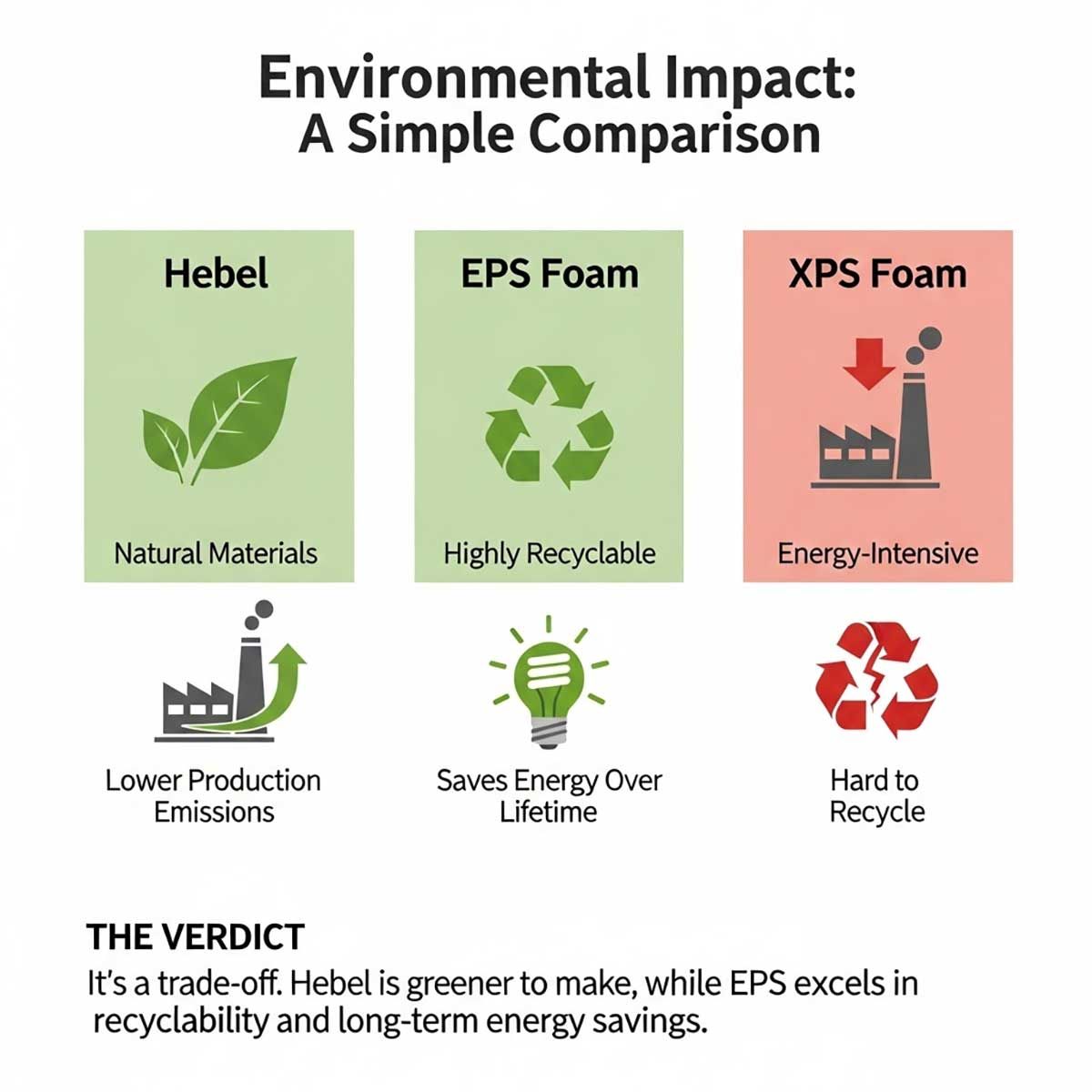

Environmental Impact: The Sustainability Comparison

Hebel Environmental Profile

- Global Warming Potential: 14.6 kg CO₂-eq/m² (verified EPD data)

- Embodied energy: 137 MJ/m² (cradle-to-gate)

- Raw materials: Natural resources (sand, lime, cement)

- Recyclability: Manufacturing waste recycled; end-of-life challenging due to render contamination and steel reinforcement

EPS Environmental Profile

- Global Warming Potential: Higher initially due to petrochemical origin

- Embodied energy: High upfront, but EPS saves up to 200x its resource investment through thermal performance

- Raw materials: Petroleum-based polystyrene

- Recyclability: 100% recyclable when clean; EPSA StyroCycle collection programs available

XPS Environmental Profile

- Global Warming Potential: Higher than EPS due to more energy-intensive manufacturing

- Embodied energy: Highest of the three, but offset by operational energy savings

- Raw materials: Petroleum-based polystyrene

- Recyclability: More difficult to recycle than EPS; fewer collection programs

Environmental winner: Complex trade-off. Hebel uses natural materials with lower production emissions. EPS is highly recyclable and saves significant energy over its lifetime. XPS manufacturing is more energy-intensive and harder to recycle than EPS.

Common Limitations to Know

Hebel Limitations

- Higher upfront cost than frame + EPS

- Needs specialist installers (scheduling bottleneck)

- Requires quality external coating system

- Heavier (foundation considerations)

EPS Limitations

- Zero structural capacity

- Combustible core (fire risk)

- Soft foam easily damaged

- Chemical sensitivity issues

XPS Limitations

- Higher cost than EPS

- Zero structural capacity

- More difficult to recycle than EPS

- Combustible core (fire risk)

Risk mitigation: We always factor these limitations into our project planning and material selection process.

Making the Right Choice for Your Project

Ask yourself these key questions:

- Do I need load-bearing walls? → Hebel

- Is this pure insulation work? → EPS or XPS

- Am I in a bushfire zone? → Hebel

- Is budget the main concern? → EPS

- Do I need maximum R-value and moisture resistance? → XPS

- Is noise a problem? → Hebel

Project-Specific Recommendations

New family home in bushfire area: Hebel external walls + EPS roof insulation

Renovation adding insulation: EPS over existing structure

Duplex or townhouse: Hebel for acoustic separation

Under-slab or basement insulation: XPS for strength and water resistance

Budget-conscious build: Frame + EPS system

Luxury home near airport: Hebel throughout for acoustic comfort

The Verdict: It's Not Either/Or

After hundreds of installations, we've learned that the best approach often combines materials. Hebel excels as an integrated structural wall system with excellent fire and acoustic properties. EPS delivers unmatched insulation value at lower cost. XPS provides a premium, high-performance solution for demanding applications where strength and moisture resistance are critical.

The winning strategy? Use each material where its strengths matter most. Hebel for structure and compliance, XPS for high-load or wet areas, and EPS for general thermal performance.

Ready to Build with the Right Material?

Choosing between Hebel, EPS, and XPS foam isn't just about comparing spec sheets - it's about understanding your specific project needs and local Sydney requirements.

Don't risk your project with inexperienced installers. AAC and polystyrene installation requires specialized knowledge that only comes from hands-on experience. Whether you choose Hebel, EPS, XPS, or our recommended hybrid approach, we've got the expertise to deliver a quality result.

Ready to make the right material choice for your Sydney project?

Give us a call today on (02) 9604 0422 or fill out our contact form. We're happy to provide a no-obligation consultation and share real examples of our recent Hebel, EPS, and XPS installations.

Our experienced team can guide you through:

- Material selection based on your specific needs

- Installation timelines and logistics

- Building code compliance requirements

- Long-term maintenance recommendations

Let's build it right the first time.