Stuck between Hebel vs brick for your next build? We've witnessed many Sydney homeowners wrestling with this exact same dilemma.

At Corebuild Services, we've been getting our hands dirty with both materials on hundreds of Sydney projects. We've seen what works, what doesn't and frankly, we've made all the mistakes so you don't have to.

Let's cut through the sales talk and get real about what each option brings to the table in 2025.

Introduction to Construction Materials

Nothing impacts your build more than what it's made from. Selecting the right building materials is crucial for any construction project. Get this wrong and you'll be kicking yourself for decades – get it right and you'll hardly think about it again.

Hebel panels are taking off lately in the construction industry. These hebel wall panels made of autoclaved aerated concrete (AAC) are winning over Sydney builders who need quick, energy efficient solutions for their external walls. Made from a mix of cement, lime, water, aluminium and sand, they're surprisingly strong despite feeling light as a feather when you pick them up.

Traditional bricks haven't survived thousands of years by accident. Our brick walls throughout Western Sydney have stood tough through everything Australian weather throws at them. There's something reassuring about solid brick houses that many home builders still prefer, despite the longer build time.

For those who want the look without the weight, brick veneer gives you that classic appearance with less structural demand on your foundations.

Some people go the cladding route, wrapping their structure in anything from timber to metal, with hebel cladding bridging both worlds nicely.

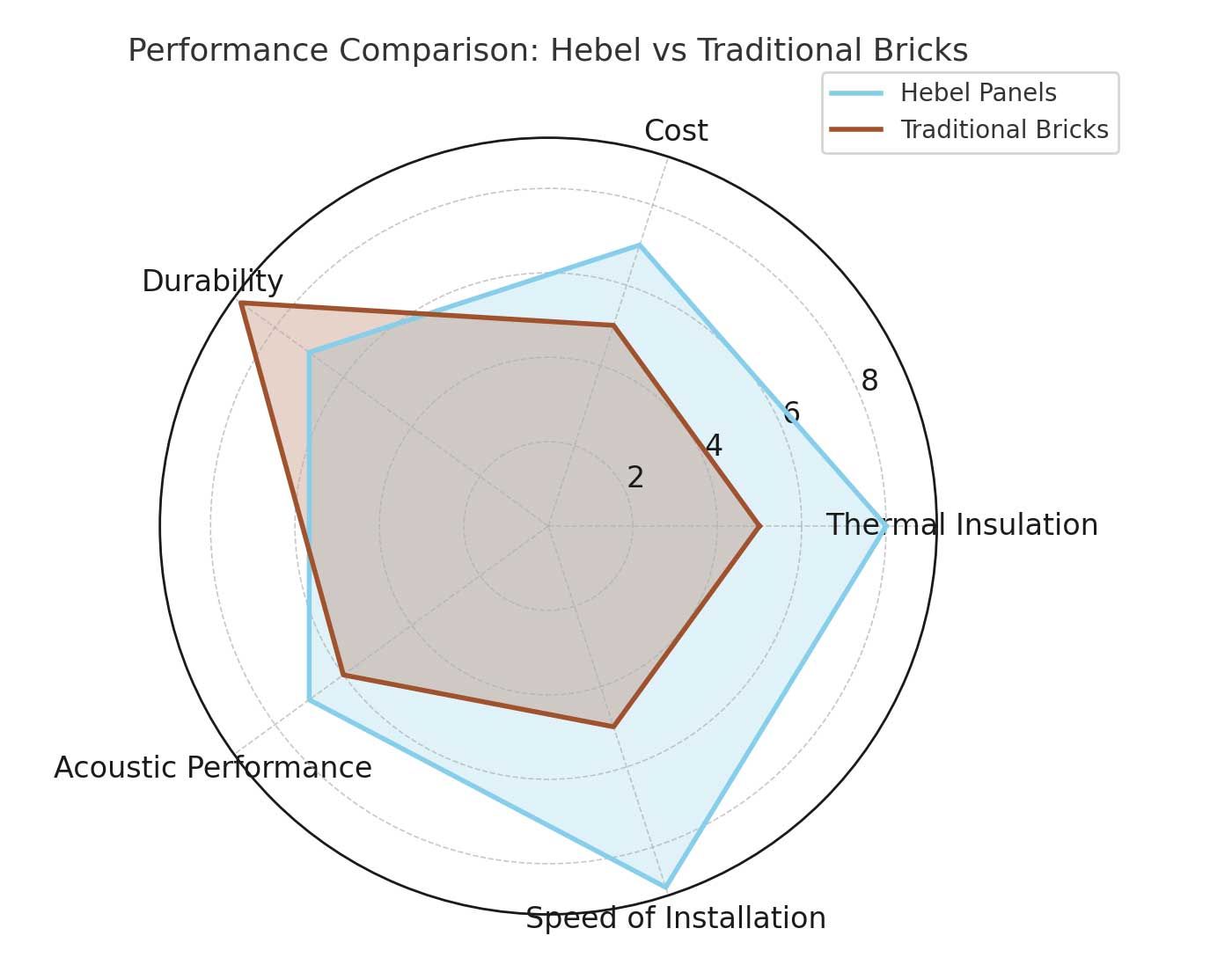

When weighing up what's best for your building projects, we always look at three key factors: thermal insulation value (R-value), sound insulation properties, ongoing maintenance needs and upfront vs lifetime costs.

Key Takeaways

- Go with Hebel when: You need to build quick (up to 60% faster than brick), want lower energy bills or have a limited budget.

- Stick with brick when: You need maximum strength, prefer traditional look or want proven multi-generation durability.

- Your decision should factor in: Build speed, energy costs, local climate, budget constraints and aesthetic preferences.

Understanding Hebel Wall Panels

We've seen solid hebel panels go from niche product to mainstream favourite over the past decade. Our site managers love the speed, our clients love the energy savings and our tradies love the lighter lifting compared to lugging bricks around all day.

What are Hebel panels made of?

Hebel's autoclaved aerated concrete is a pretty simple mix: cement, sand, lime, gypsum and aluminium powder that creates tiny air bubbles throughout. Think of it like a hebel concrete version of an Aero chocolate bar – solid but full of little air pockets that make it surprisingly lightweight.

We've cut through countless hebel panels and they're nothing like working with dense concrete or brick. To boost durability and prevent cracking, manufacturers reinforce the panels with anti corrosion steel reinforcement – crucial for maintaining structural integrity over decades.

Key features of Hebel panels

The weight difference is massive – Hebel weighs about 80% less than equivalent brick. This makes a world of difference on site, especially when you're seven hours into a summer workday on rear external walls.

The insulation performance is where Hebel really shines as an ideal building material. Our clients in areas like Penrith and Richmond who cop the worst of Sydney's summer heat report noticeably more comfortable indoor temperatures and smaller energy bills after switching from brick to Hebel walls.

Those air pockets we mentioned? They don't just reduce weight – they create an effective sound insulation barrier. Our clients near main roads or flight paths particularly notice this benefit.

Visually Hebel provides clean lines and modern aesthetics that contemporary architects in the construction industry love working with. The material takes renders beautifully giving designers plenty of finish options for construction materials.

Exploring Brick as a Building Material

Traditional bricks remain popular for good reason in the construction industry. Some of the first brick structures date back to 8300 B.C. and they're still standing. That says something about brick as an ideal building material.

We recently inspected a century-old brick home Balmain where the original brick walls remained remarkably solid despite enduring decades of harsh Australian weather conditions. This impressive durability is why brick continues to be considered alongside newer construction materials.

Composition and types of bricks

Traditional bricks contain natural clay and shale, fired at high temperatures to create extremely durable building units. The beauty of brick lies in its simplicity – these basic components create something that can literally last centuries.

Cement based bricks offer consistent shapes and sizes while kiln fired varieties provide those earthy colours that give brick houses their character. We've used bricks for everything from main structures to garden features, retaining walls and even outdoor kitchens. Their natural composition means excellent termite resistance and impressive structural performance in extreme conditions.

Advantages of using bricks

Nothing beats brick for sheer strength and proven longevity. When we're building in areas prone to extreme conditions, brick walls often remain our go-to recommendation for every construction project.

The thermal mass of brick works brilliantly in Sydney's climate, absorbing heat during the day and slowly releasing it overnight – natural temperature regulation that's been working for centuries.

Being non-combustible, brick provides superior fire resistance – particularly important for bushfire prone areas.

The earthy colour palette gives homes that timeless look that never seems to date, while their moisture management reduces mould issues that can plague other materials.

Despite higher initial labour costs, brick's minimal maintenance needs make it cost effective over a building's lifetime – something savvy homeowners in the construction industry factor into their decisions.

Comparing Hebel Wall Panels and Bricks

Having built with both construction materials we've seen firsthand how they stack up against each other across different scenarios and conditions.

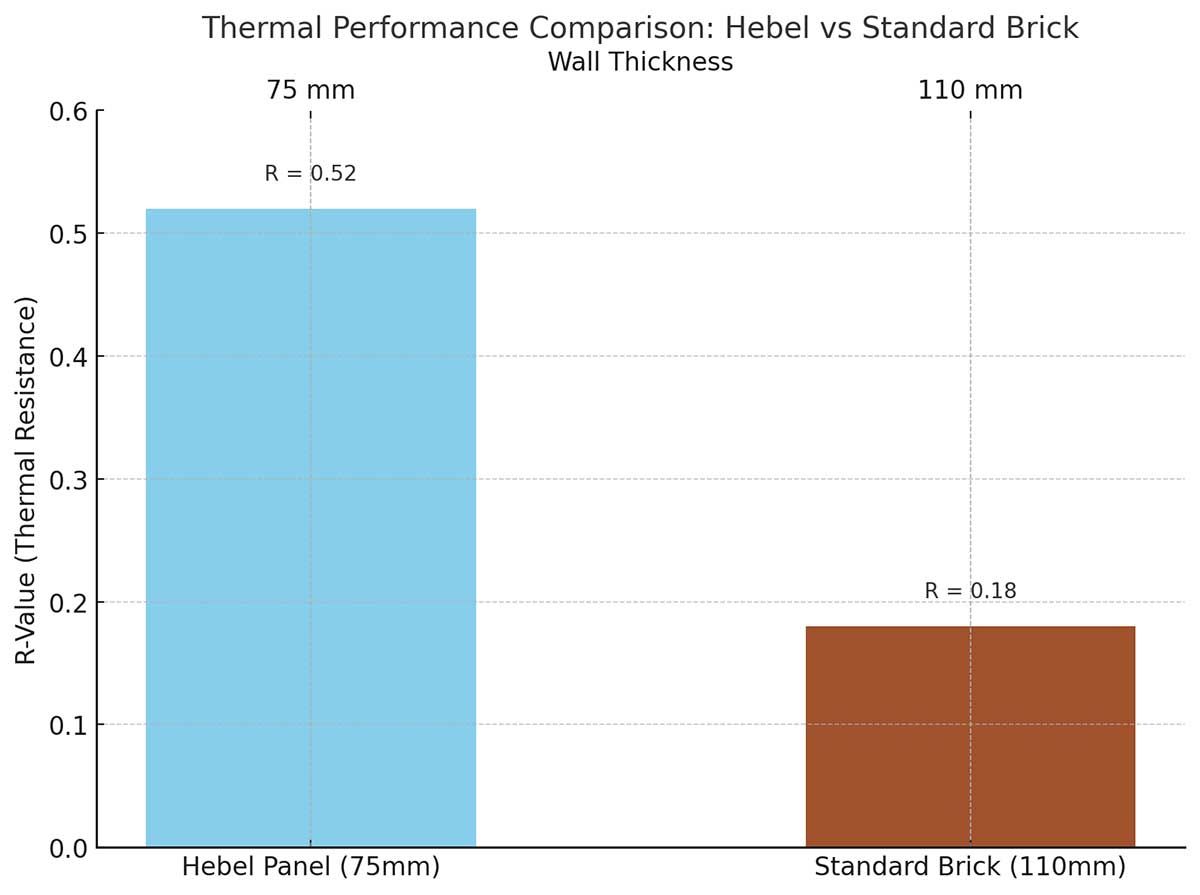

Hebel's autoclaved aerated concrete delivers impressive thermal performance, noise reduction and fire resistance compared to standard masonry. Our testing shows Hebel panels can outperform brick walls by up to six times in R-value, translating to significantly lower heating and cooling costs throughout the year.

We've noticed Hebel wall panels' design eliminates many common moisture problems associated with brick construction. The absence of weep holes reduces risks of water intrusion and pest access – issues we've had to remediate in older brick houses.

The speed difference is substantial. One large Hebel panel replaces up to 90 individual bricks, cutting construction time dramatically. A recent Corebuild project in Liverpool reached lock up stage nearly three weeks earlier using Hebel walls instead of the originally specified brick walls for both external walls and internal partitions.

That said brick's superior compressive strength and timeless aesthetic appeal make it irreplaceable for certain applications. Many of our heritage loving clients specifically request traditional bricks despite understanding the longer construction timeline and additional costs involved for their building projects.

Key Advantages of Hebel Wall Panels

Installation process

We've refined our Hebel installation process to maximise efficiency on site. The panels come in both large sheets and smaller blocks, giving our teams flexibility for different construction elements. To put it in perspective: a skilled worker can install a single 3-metre Hebel panel (equivalent to about 90 bricks) in roughly 20 minutes. The same area in brick? That's most of a day's work for an experienced bricklayer.

Our project data shows Hebel constructions typically reach weather tight stage 2-3 weeks faster than comparable brick builds. This allows internal trades to start earlier, potentially compressing overall build schedules by a month or more on larger projects.

Performance in energy efficiency

Real world energy monitoring on our completed projects consistently shows Hebel outperforming in temperature regulation and energy efficiency. Homes maintain more stable internal temperatures regardless of outside conditions.

The superior thermal properties mean most clients see immediate results on their energy bills. Several homeowners have shared 25-30% reductions in cooling costs during Sydney's brutal summer months after switching from brick to Hebel construction.

While brick walls also provide good thermal mass, Hebel's combination of insulation and thermal properties creates a more complete energy efficient solution, making it increasingly popular with our eco and budget conscious clients.

Cost considerations

Our project data shows Hebel typically reduces overall construction costs compared to traditional brick. The material itself isn't necessarily cheaper, but the savings come from:

- Reduced labour hours (fewer workers needed for less time)

- Faster project completion (reducing financing costs)

- Simplified logistics (fewer deliveries and less site storage)

Maintenance costs also tend to be lower with Hebel. Unlike some brick installations that might need periodic repointing or treatments, Hebel panels require minimal upkeep while maintaining their structural integrity and appearance over decades.

Limitations of Hebel Panels

While we recommend Hebel for many applications, transparency matters. Hebel's reduced compressive strength compared to structural brick makes it better suited for low to medium height constructions.

On multi level projects we often specify brick for ground floors to provide optimal structural support, with Hebel used for upper levels where its lighter weight becomes advantageous.

Hebel typically requires rendering or similar finishing for both weatherproofing and aesthetics. Brick, conversely, often looks great in its natural state without additional surface treatments – a factor in overall project planning and budgeting.

Environmental impact

Environmental impact of Hebel panels

As builders increasingly focused on sustainable construction we appreciate that Hebel wall panels contain natural materials and are fully recyclable. Solid hebel panels' lightweight composition reduces transport emissions – a small but meaningful contribution to reducing environmental impact. Industry stats show Hebel's autoclaved aerated concrete production generates less CO2 than traditional concrete production. Compared to brick over the whole lifecycle, Hebel is about 30% less environmental impact – a big deal for our eco-conscious clients planning building projects.

Environmental impact of bricks

Traditional brick production involves very high firing temperatures, huge energy consumption and carbon emissions. Extracting clay for brick walls can disrupt landscapes and affect local biodiversity in the construction industry.

Brick kilns contribute to particulate pollution in many manufacturing regions globally – something we rarely consider in material selection but increasingly important for our environmentally aware clients looking for the ideal building material.

That's why we recommend Hebel concrete more often for our green building clients who want superior thermal insulation and better sound insulation.

Choosing the Right Material for Your Project

At Corebuild Services we know there's no one-size-fits-all answer. The right material depends on your project, site, budget, and personal preferences.

Hebel offers modern look, faster construction, better energy performance and often lower initial cost. Clean lines and rendering options give contemporary visual appeal that can boost street presence and resale value.

Brick gives you structural integrity, proven longevity and classic look with minimal maintenance. For heritage areas or traditional design, brick is hard to beat.

We're always collaborative – we assess your project, site and preferences before making recommendations tailored to your situation.

Summary

After working with both materials on hundreds of Sydney projects we have a deep understanding of their strengths and limitations.

Hebel is fast, efficient, cost effective and environmentally friendly. Brick is unbeatable for structural strength, durability, classic look and low maintenance.

By knowing both options well you can make an informed decision that suits your priorities. Whether you want modern efficiency or timeless longevity, Corebuild Services can guide you to the right material for your project.

Frequently Asked Questions

What are Hebel panels made of?

Hebel panels are made from autoclaved aerated concrete (AAC) – a mix of cement, sand, lime, gypsum and aluminum powder that creates tiny air pockets throughout the concrete. This special composition makes a material that's surprisingly lightweight yet structurally sound with excellent thermal insulation and energy efficiency.

How do Hebel wall panels compare to brick walls in terms of energy efficiency?

Based on before-and-after monitoring of identical floor plans, Hebel's autoclaved aerated concrete outperforms traditional bricks by up to 6 times better thermal insulation. Our clients get 20-30% reduction in heating and cooling costs after switching to Hebel for their external walls.

What are the environmental benefits of using Hebel panels?

Hebel offers several eco-friendly benefits: natural materials, fully recyclable, lighter weight reduces transport emissions, lower ongoing energy usage. Hebel production generates less carbon than traditional brick production, making it an ideal building material for environmentally conscious construction projects.

Are Hebel panels cost-effective compared to bricks?

Our project data shows cost savings with Hebel walls. While material costs can be similar, the huge reduction in labour time and associated costs makes Hebel more economical for building projects. Faster construction also reduces financing costs on larger projects in the construction industry. For detailed pricing information, check out our 2025 Hebel price list featuring blocks, panels, and powerfloor prices.

What are the limitations of Hebel wall panels?

While we recommend Hebel for many projects, it has limitations. Compared to structural brick, Hebel has less compressive strength so is better suited for low to medium height buildings. Solid hebel panels require rendering for weatherproofing and aesthetics, while brick houses can be left exposed. For rear external walls that need maximum strength, brick might still be preferred.